Feed Pre-heater, Titanium Plate Heat Exchanger by Hessa-South Africa

Sodium Sulphate Crystalliser Plant, ASS Feed Pre-heater, duty carried by two units of Titanium Plate Heat Exchanger.

Project accompalished by HESSA, South Africa Team

Project accompalished by HESSA, South Africa Team

DETAIL

Sodium Sulphate Crystalliser Plant, ASS Feed Pre-heater, duty carried by two units of Titanium Plate Heat Exchanger; Process Condensate Cooler, duty is carried by one unit of SS316 Plate Heat Exchanger. Project accomplished by HESSA, South Africa Team

In Sodium Sulphate Crystalliser Plant, Plate Heat Exchanger act as ASS Feed Pre-heater for High Temperature condensate cooling, meanwhile Feed Liquor is pre-heated by condensate.

In view of High Corrosive feature of Feed Liquor, we use positive 0.5mm Titanium material sheet as Plates. The Titanium raw material comes from Nippon of Japan, the Titanium Composition is 99.5%. Furthermore, SHINEHEAT procurement is all Positive Allowance in Titanium plate thickness, generally not less than 0.48mm after pressing. It is contribute longer service life for SHINEHEAT Plate Heat Exchanger.

In order to make qualified products, the Feed Liquor need to reach specific temperature range. This job is implemented by High efficient Plate type heat exchanger.

Now SHINEHEAT provide a model of AT150B Plate heat exchanger for this duty

Following is design data sheet of plate heat exchanger.

Item: Process Plant 614-313

____________________________________________________________________________________________

SHINEHEAT Plate Heat Exchanger Technical Specification

____________________________________________________________________________________________________________

2*AT100-B Titanium 0.50 mm 157/159pl 58.9/60.1 m²

pdes=5.0 barg Tdes=55.0/50.0-115.0/110.0 °C k=4836/4019 W/(m²*K) Marg.=20(20)% Foul.=0.0(0.42)*10-4 m²*K/W

Load=869.5 kW LMTD=3.7 K

Condensate 13.8 m³/h 68.6<80.0 kPa 112.0 °C --> 55.0 °C 3*16H

Feed Liquor Mp 12.5 m³/h 76.2<80.0 kPa 109.4 °C <-- 50.0 °C 3*16H

Dp(p+co)=0.0928 kPa v(co)=0.217 m/s NTU=15.53 Conn 1/1 150.0 mm

Dp(p+co)=0.105 kPa v(co)=0.198 m/s NTU=16.18 Conn 1/1 150.0 mm

Media Temp. Dens. Sp.heat. Cond. Visc.

Water 55.0 984.5 4.17 0.648 0.503

88.1 966.6 4.19 0.675 0.321

112.0 950.2 4.23 0.686 0.250

Feed Liquor Mp 50.0 1238.0 3.40 0.440 1.00

84.5 1234.5 3.40 0.440 0.497

109.4 1232.1 3.40 0.440 0.300

Temperatures

Side 1 Side 2

Bulk 112.0 54.5 m(ch) 819 969

Wall 111.2 52.8 v(neck) 0.489 0.446

Wall 111.0 52.4 v(ch) 0.213 0.194

Bulk 110.0 50.0 tau(wall) 20.7 23.0

Bulk or wall temp. out of range side 2

Warning: Theta (15.5) >= 10. Results may be unreliable. Contact thermal specialist at application center

By many years’ supplying experience in industry, we design optimal model of plate heat exchanger by both thermal efficiency, pressure drop and size economical, also take future capacity expansion into consideration, so you will find our enough length in Carrying and Guarding Bar of plate heat exchanger.

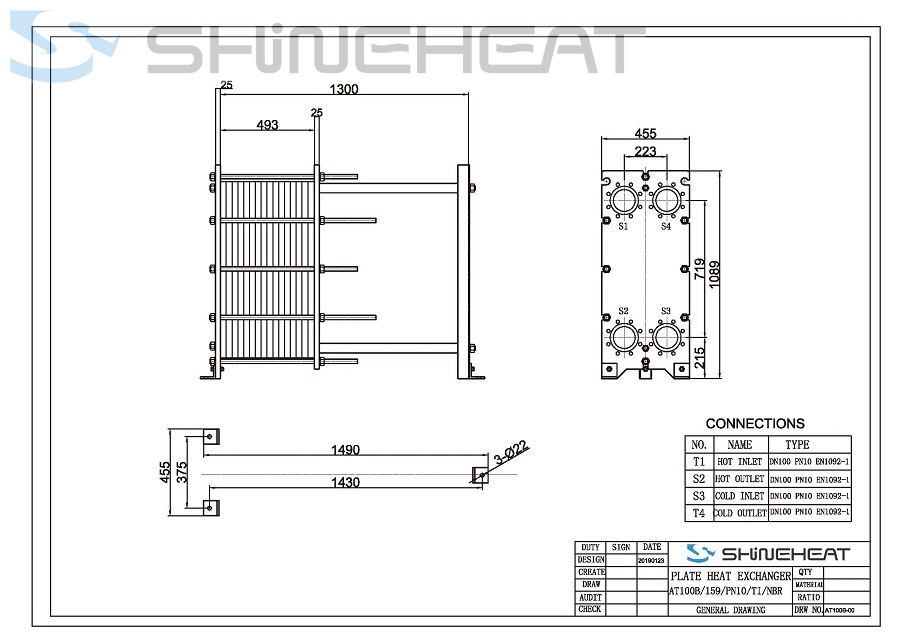

The Design Drawing for Plate Heat Exchanger

The Plate Heat Exchanger Supply Scope

In order to take good use of international collaboration among HESSA Members. Shineheat-HESSA China is providing Pre-assembly Plate Heat Exchanger Unit, the final assemble is finished by IWC-HESSA South Africa. Under this way, the Transportation Cost and Import Tax are reduced.

For Process Condensate Cooler, duty is carried by one unit of SS316 Plate Heat Exchanger.

SHINEHEAT provide a model of AT60B Plate heat exchanger for this duty

Following is design data sheet of plate heat exchanger.

Item: Process Plant 614-315

____________________________________________________________________________________________________________

SHINEHEAT Plate Heat Exchanger Technical Specification

_____________________________________________________________________________________________

1*AT60B AISI 316 0.50 mm 57/59pl 8.6/8.9 m²

pdes=5.0 barg Tdes=30.0/25.0-65.0/40.0 °C k=5426/4522 W/(m²*K) Marg.=20(20)% Foul.=0.0(0.37)*10-4 m²*K/W

Load=455.8 kW LMTD=11.8 K

Water 13.4 m³/h 12.7<80.0 kPa 63.0 °C --> 33.0 °C 1* (14H+15ML)

Water 32.9 m³/h 75.1<80.0 kPa 40.0 °C <-- 28.0 °C 1* (14H+15MH)

Dp(p+co)=1.38 kPa v(co)=1.89 m/s NTU=2.54 Conn 1/1 50.0 mm

Dp(p+co)=8.65 kPa v(co)=4.67 m/s NTU=1.02 Conn 1/1 50.0 mm

Media Temp. Dens. Sp.heat. Cond. Visc.

Water 33.0 993.4 4.18 0.621 0.752

42.5 989.8 4.18 0.633 0.624

63.0 980.7 4.17 0.655 0.445

Water 28.0 995.0 4.18 0.614 0.836

31.8 993.8 4.18 0.620 0.770

40.0 990.8 4.18 0.630 0.654

Temperatures

Side 1 Side 2

Bulk 63.0 30.2 m(ch) 358 867

Wall 51.6 29.0 v(neck) 0.604 1.45

Wall 48.5 28.7 v(ch) 0.235 0.563

Bulk 41.6 28.0 tau(wall) 16.4 95.3

Bulk 63.0 32.5 m(ch) 539 1370

Wall 50.7 30.0 v(neck) 0.909 2.29

Wall 47.2 29.4 v(ch) 0.353 0.890

Bulk 40.0 28.0 tau(wall) 16.3 96.2

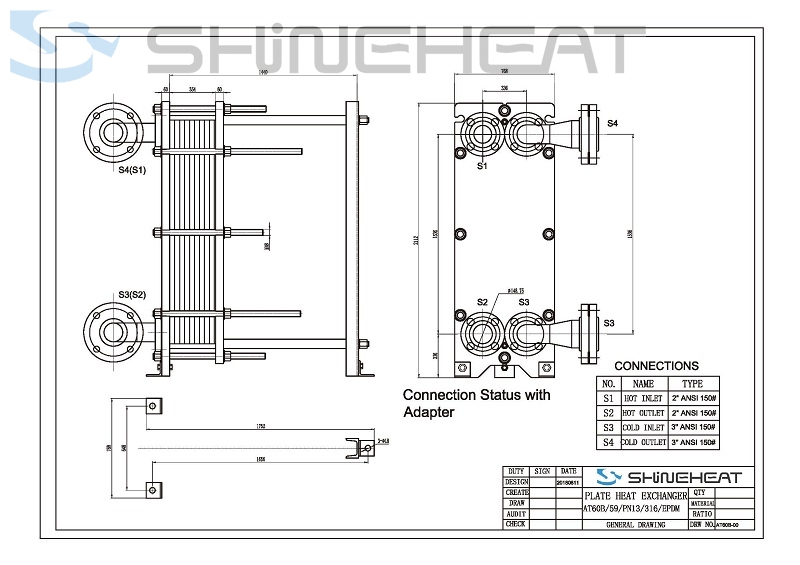

The Design Drawing for Plate Heat Exchanger

The Plate Heat Exchanger Supply Scope

In order to take good use of international collaboration among HESSA Members. Shineheat-HESSA China is providing Pre-assembly Plate Heat Exchanger Unit, the final assemble is finished by IWC-HESSA South Africa. Under this way, the Transportation Cost and Import Tax are reduced.

At Site, New plate heat exchanger installed and operated very successfully, up to now it is running on good condition and performance.

In Sodium Sulphate Crystalliser Plant, Plate Heat Exchanger act as ASS Feed Pre-heater for High Temperature condensate cooling, meanwhile Feed Liquor is pre-heated by condensate.

| Feed Liquor Composition | |

| Na2SO4 wt% | 25.8 |

| NaCl wt% | 0.4 |

| K2SO4 wt% | 0.4 |

| PH | 8-9 |

| Max Total Chlorides | 5000 ppm |

In view of High Corrosive feature of Feed Liquor, we use positive 0.5mm Titanium material sheet as Plates. The Titanium raw material comes from Nippon of Japan, the Titanium Composition is 99.5%. Furthermore, SHINEHEAT procurement is all Positive Allowance in Titanium plate thickness, generally not less than 0.48mm after pressing. It is contribute longer service life for SHINEHEAT Plate Heat Exchanger.

In order to make qualified products, the Feed Liquor need to reach specific temperature range. This job is implemented by High efficient Plate type heat exchanger.

Now SHINEHEAT provide a model of AT150B Plate heat exchanger for this duty

Following is design data sheet of plate heat exchanger.

Item: Process Plant 614-313

____________________________________________________________________________________________

SHINEHEAT Plate Heat Exchanger Technical Specification

____________________________________________________________________________________________________________

2*AT100-B Titanium 0.50 mm 157/159pl 58.9/60.1 m²

pdes=5.0 barg Tdes=55.0/50.0-115.0/110.0 °C k=4836/4019 W/(m²*K) Marg.=20(20)% Foul.=0.0(0.42)*10-4 m²*K/W

Load=869.5 kW LMTD=3.7 K

Condensate 13.8 m³/h 68.6<80.0 kPa 112.0 °C --> 55.0 °C 3*16H

Feed Liquor Mp 12.5 m³/h 76.2<80.0 kPa 109.4 °C <-- 50.0 °C 3*16H

Dp(p+co)=0.0928 kPa v(co)=0.217 m/s NTU=15.53 Conn 1/1 150.0 mm

Dp(p+co)=0.105 kPa v(co)=0.198 m/s NTU=16.18 Conn 1/1 150.0 mm

Media Temp. Dens. Sp.heat. Cond. Visc.

Water 55.0 984.5 4.17 0.648 0.503

88.1 966.6 4.19 0.675 0.321

112.0 950.2 4.23 0.686 0.250

Feed Liquor Mp 50.0 1238.0 3.40 0.440 1.00

84.5 1234.5 3.40 0.440 0.497

109.4 1232.1 3.40 0.440 0.300

Temperatures

Side 1 Side 2

Bulk 112.0 54.5 m(ch) 819 969

Wall 111.2 52.8 v(neck) 0.489 0.446

Wall 111.0 52.4 v(ch) 0.213 0.194

Bulk 110.0 50.0 tau(wall) 20.7 23.0

Bulk or wall temp. out of range side 2

Warning: Theta (15.5) >= 10. Results may be unreliable. Contact thermal specialist at application center

By many years’ supplying experience in industry, we design optimal model of plate heat exchanger by both thermal efficiency, pressure drop and size economical, also take future capacity expansion into consideration, so you will find our enough length in Carrying and Guarding Bar of plate heat exchanger.

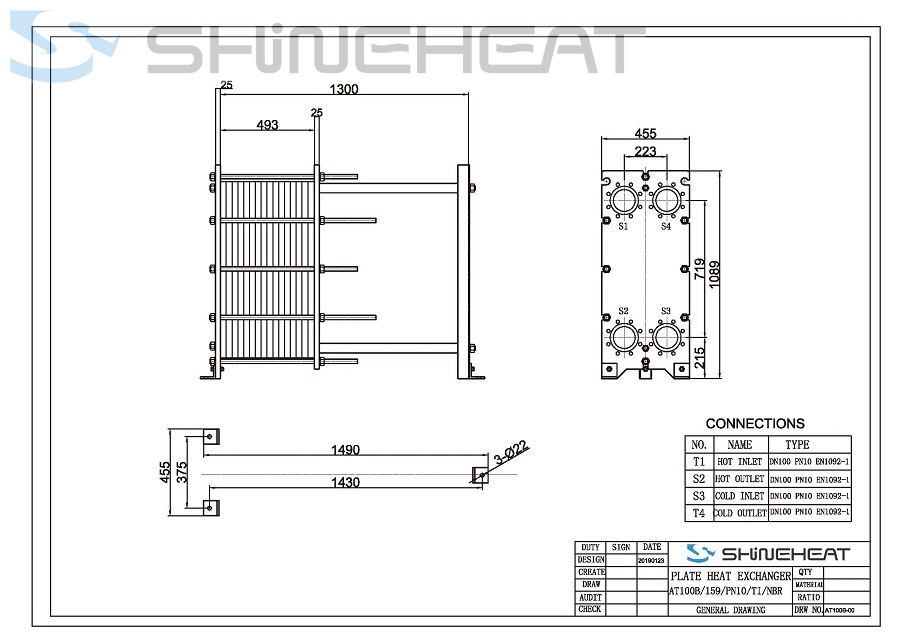

The Design Drawing for Plate Heat Exchanger

The Plate Heat Exchanger Supply Scope

In order to take good use of international collaboration among HESSA Members. Shineheat-HESSA China is providing Pre-assembly Plate Heat Exchanger Unit, the final assemble is finished by IWC-HESSA South Africa. Under this way, the Transportation Cost and Import Tax are reduced.

For Process Condensate Cooler, duty is carried by one unit of SS316 Plate Heat Exchanger.

SHINEHEAT provide a model of AT60B Plate heat exchanger for this duty

Following is design data sheet of plate heat exchanger.

Item: Process Plant 614-315

____________________________________________________________________________________________________________

SHINEHEAT Plate Heat Exchanger Technical Specification

_____________________________________________________________________________________________

1*AT60B AISI 316 0.50 mm 57/59pl 8.6/8.9 m²

pdes=5.0 barg Tdes=30.0/25.0-65.0/40.0 °C k=5426/4522 W/(m²*K) Marg.=20(20)% Foul.=0.0(0.37)*10-4 m²*K/W

Load=455.8 kW LMTD=11.8 K

Water 13.4 m³/h 12.7<80.0 kPa 63.0 °C --> 33.0 °C 1* (14H+15ML)

Water 32.9 m³/h 75.1<80.0 kPa 40.0 °C <-- 28.0 °C 1* (14H+15MH)

Dp(p+co)=1.38 kPa v(co)=1.89 m/s NTU=2.54 Conn 1/1 50.0 mm

Dp(p+co)=8.65 kPa v(co)=4.67 m/s NTU=1.02 Conn 1/1 50.0 mm

Media Temp. Dens. Sp.heat. Cond. Visc.

Water 33.0 993.4 4.18 0.621 0.752

42.5 989.8 4.18 0.633 0.624

63.0 980.7 4.17 0.655 0.445

Water 28.0 995.0 4.18 0.614 0.836

31.8 993.8 4.18 0.620 0.770

40.0 990.8 4.18 0.630 0.654

Temperatures

Side 1 Side 2

Bulk 63.0 30.2 m(ch) 358 867

Wall 51.6 29.0 v(neck) 0.604 1.45

Wall 48.5 28.7 v(ch) 0.235 0.563

Bulk 41.6 28.0 tau(wall) 16.4 95.3

Bulk 63.0 32.5 m(ch) 539 1370

Wall 50.7 30.0 v(neck) 0.909 2.29

Wall 47.2 29.4 v(ch) 0.353 0.890

Bulk 40.0 28.0 tau(wall) 16.3 96.2

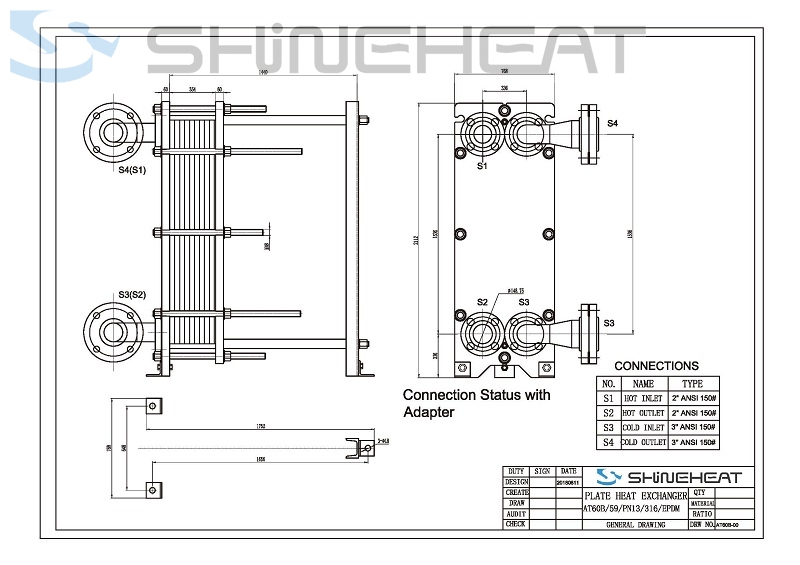

The Design Drawing for Plate Heat Exchanger

The Plate Heat Exchanger Supply Scope

In order to take good use of international collaboration among HESSA Members. Shineheat-HESSA China is providing Pre-assembly Plate Heat Exchanger Unit, the final assemble is finished by IWC-HESSA South Africa. Under this way, the Transportation Cost and Import Tax are reduced.

At Site, New plate heat exchanger installed and operated very successfully, up to now it is running on good condition and performance.