Plate Evaporators: A Key Technology in Sugarcane Processing

Enhancing Efficiency and Reliability in Sugar Processing Plants with Plate Evaporators

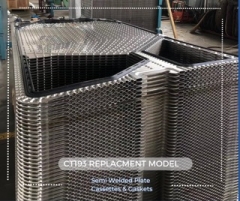

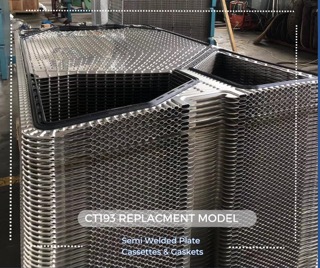

Plate evaporators are widely used in the sugar industry for their high efficiency in concentrating sugar cane juice. As large-scale sugar factories increase their production capacity, the demand for high-capacity plate evaporators continues to grow. The KELVION GEA CT193 plate evaporator is a popular choice for many sugar mills. SHINEHEAT, a professional supplier of plate evaporator accessories, offers laser semi-welded plate cassettes and gaskets that are fully compatible with the CT193 model, providing excellent cost-effectiveness and performance.

Working Principle:

Plate evaporators operate on the principle of heat transfer between two fluids. The sugar cane juice to be concentrated flows through one set of channels in the plate, while the heating medium, such as steam or hot water, flows through the alternate channels. The heat from the heating medium is transferred to the sugar cane juice, causing it to evaporate. The concentrated juice, now in the form of a syrup, is then collected at the outlet.

Advantages of Plate Evaporators:

- High efficiency: The close proximity of the heating and evaporation surfaces in plate evaporators results in high heat transfer rates, leading to efficient evaporation and concentration of sugar cane juice.

- Low energy consumption: The compact design and efficient heat transfer of plate evaporators minimize energy consumption, reducing operating costs for sugar mills.

- Easy to clean and maintain: The plate design allows for easy disassembly and cleaning, minimizing downtime and ensuring optimal performance.

- Scalability: Plate evaporators can be easily scaled up or down to meet the specific needs of different sugar factories.

The KELVION GEA CT193 Plate Evaporator:

The CT193 is a high-performance plate evaporator designed for the specific requirements of the sugar industry. It features a number of innovative design elements that contribute to its efficiency, reliability, and ease of use:

- Optimized plate design: The chevron-shaped plates promote turbulence in the fluid flow, enhancing heat transfer and minimizing fouling.

- Wide operating range: The CT193 can operate under a wide range of temperatures and pressures, making it suitable for various sugar cane juice concentrations.

- Robust construction: The evaporator is constructed from high-quality materials to withstand the harsh operating conditions in sugar mills.

SHINEHEAT CT193 Compatible Plates and Gaskets:

SHINEHEAT offers a complete range of high-quality accessories for the CT193 plate evaporator, including:

- Laser-welded heat exchange plates: These plates are manufactured using advanced laser welding technology, ensuring superior strength, durability, and corrosion resistance.

- Replacement gaskets: The gaskets are made from high-grade materials that can withstand high temperatures and pressures, preventing leaks and ensuring optimal sealing performance.

Plate evaporators are a critical technology in the sugar industry, and the KELVION GEA CT193 is a proven performer in this field. By using high-quality accessories from SHINEHEAT, sugar mills can enhance the performance, reliability, and lifespan of their CT193 evaporators while achieving optimal operational efficiency and cost-effectiveness.

"SHINEHEAT replacement gaskets seamlessly mount onto the original KELVION GEA CT193 Plate, ensuring a perfect fit!"