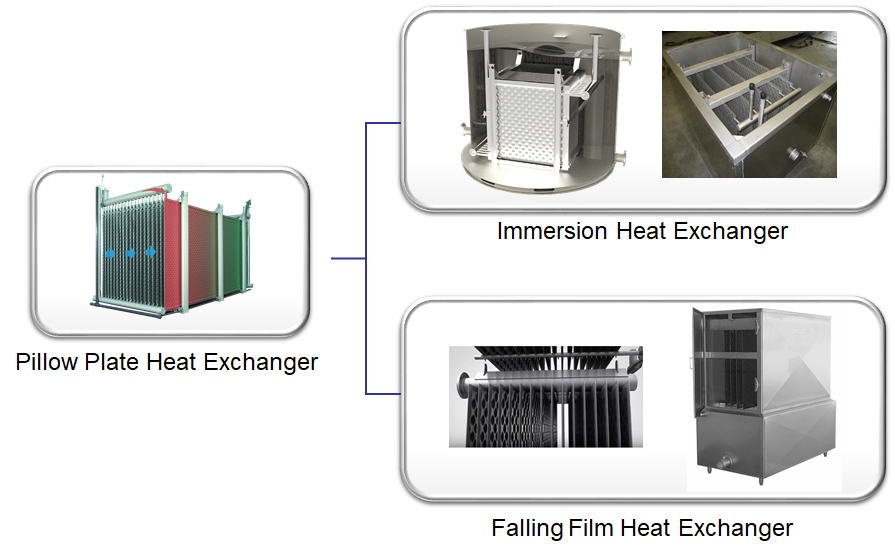

PILLOW PLATE HEAT EXCHANGER

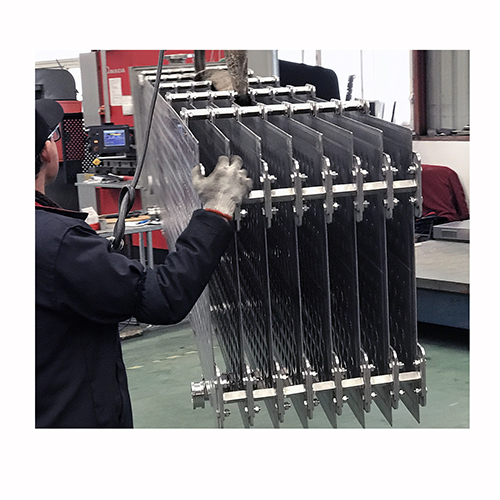

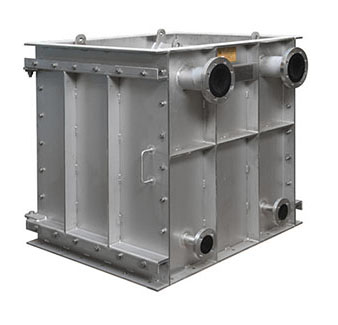

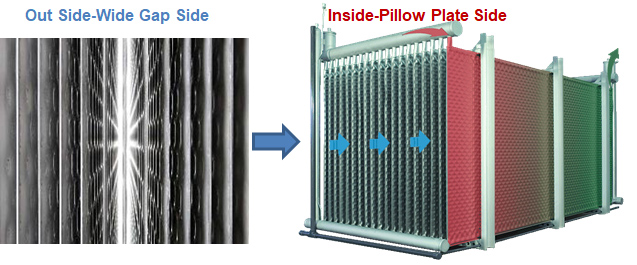

Like common Gasketed Plate Heat Exchanger, Pillow Plate Heat Exchanger realizes thermal transfer through Embossed or Corrugated plate; however, it is seal by welding not gasket. Furthermore, one side fluid goes into Embossed Pillow Plate, another side fluid goes between Embossed Pillow Plate. In view of the distance or gap of each set Pillow Plate could adjust, so it can make into Wide Gap or Free Flow Heat Exchanger for one side.

Compared with other types of Plate Heat Exchanger, Pillow Plate Heat Exchanger has its unique features and advantages, especially for fluid containing more impurities or high viscosity or complex applications. From following chart, we see various applications that Pillow Plate Heat Exchanger could engage in.

| Style | Pillow Plate Heat Exchanger | Shell Tube Heat Exchanger | Gaskeked Heat Exchanger | Spiral Heat Exchanger |

| Operation temperature range | <800℃ | <800℃ | <170℃ | <350℃ |

| Max. pressure | <60 bar | <200 bar | <32 bar | <25 bar |

| Heat transfer coefficient of water[W/m2·℃] | 3500 | 2700 | 5600 | 2000 |

| Application of air and water heat transfer | Applicable | Applicable | Not applicable | Partial applicable |

| Immersion in tank or water | Applicable | Partial applicable | Not applicable | Not applicable |

| Welded to tank and reactor | Applicable | Not applicable | Not applicable | Not applicable |

| Install into existing reaction tower and other equipment | Flexible | Partial applicable | Not applicable | Not applicable |

| All welded structure | Applicable | Applicable | Not applicable | Not applicable |

| Heavy contaminated liquids and other applications | Applicable | Applicable | Partial applicable | Applicable |

| Unit area weight | Low | High | Low | High |

| Falling film, condenser and evaporator | Applicable | Applicable | Partial applicable | Partial applicable |

As to different applications, Pillow Plate Heat Exchanger also could divided into Immersion Heat Exchanger and Falling Film Heat Exchanger.